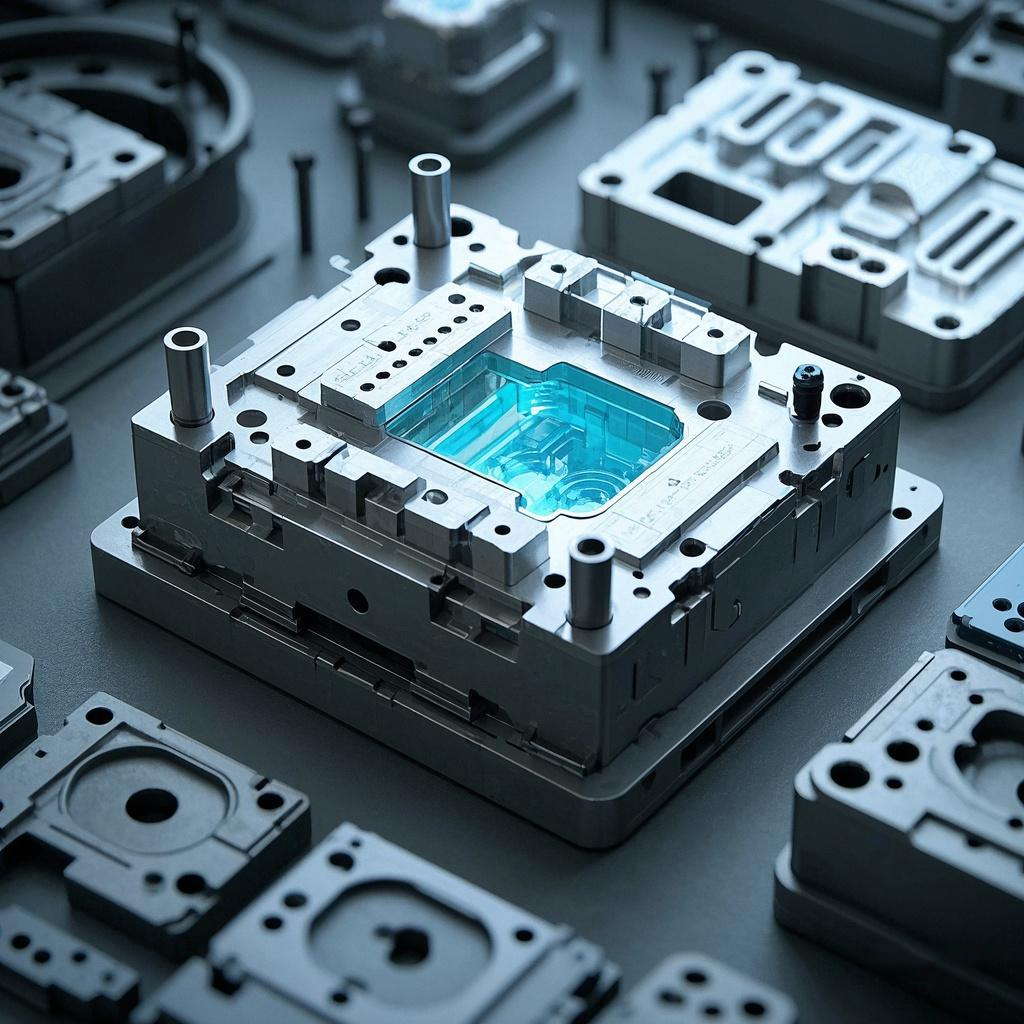

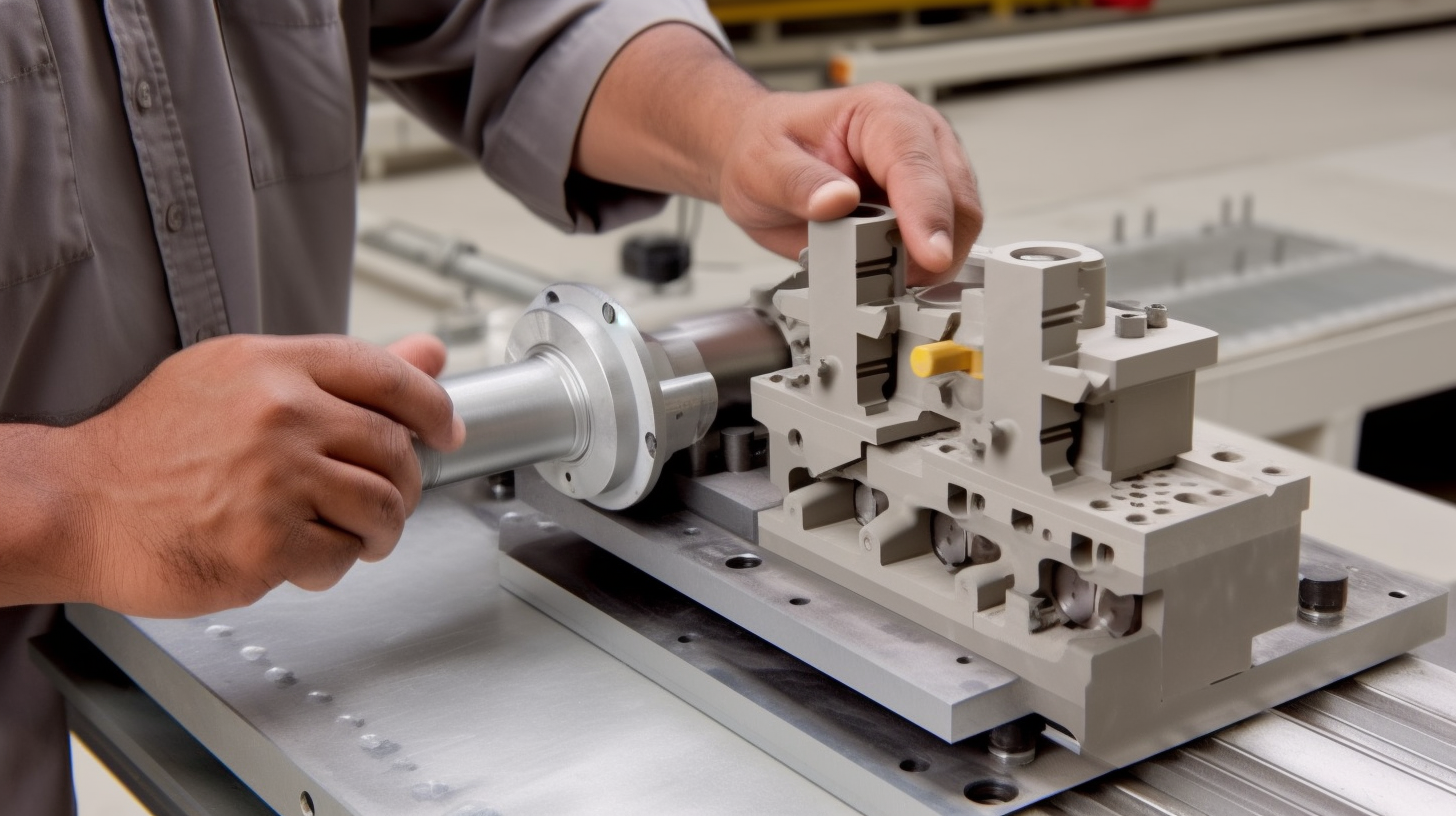

Mold design is a crucial factor in determining the quality, precision, and performance of injection-molded parts. Proper mold design ensures consistent material flow, uniform cooling, and minimal defects, leading to high-quality molded components. Poor mold design, on the other hand, can result in issues like warping, sink marks, short shots, and flash.

Let’s explore how different aspects of mold design influence the final part quality and how to optimize them.

Why Is Gate Placement Important?

Gate placement affects material flow, filling uniformity, and the likelihood of defects such as weld lines and air traps. Poorly positioned gates can cause uneven pressure distribution, leading to incomplete filling or excessive residual stress in the part.

To optimize gate placement:

Position gates near thicker sections to prevent shrinkage and voids.

Use multiple gates for large or complex parts to ensure even filling.

Avoid placing gates in high-stress areas where weld lines may weaken the part.

Proper gate placement helps achieve balanced material flow, reducing defects and improving part strength.

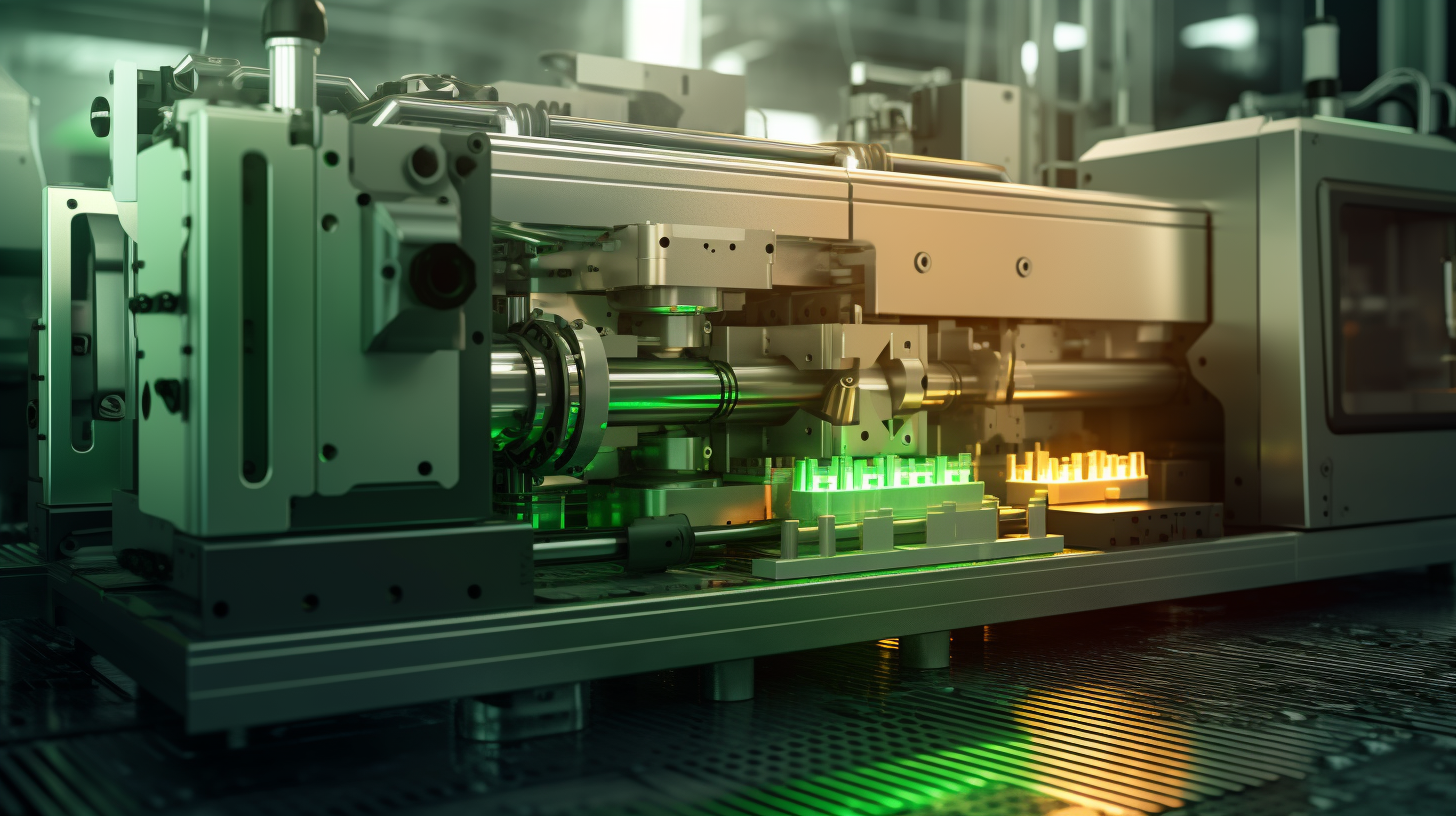

How Does Cooling System Design Affect Part Quality?

Cooling time accounts for up to 70% of the injection molding cycle and directly impacts part stability. Uneven cooling leads to warping, internal stresses, and inconsistent shrinkage.

To optimize cooling:

Use conformal cooling channels that follow the part’s geometry for uniform heat dissipation.

Ensure balanced cooling circuits to prevent temperature variations across the mold.

Reduce cycle times without causing defects by using high-conductivity mold materials.

An efficient cooling system ensures dimensional accuracy, prevents warping, and improves production efficiency.

What Role Does Venting Play in Mold Design?

Venting allows trapped air and gases to escape, preventing burn marks, voids, and short shots. Without proper venting, air pockets can form, leading to surface defects and weak spots in the part.

Best practices for venting:

Place vents at the end of flow paths to allow trapped air to escape.

Keep vent channels small enough to prevent material leakage but large enough to release gases.

Regularly clean vents to prevent buildup of plastic residue.

Good venting ensures defect-free parts with smooth surface finishes.

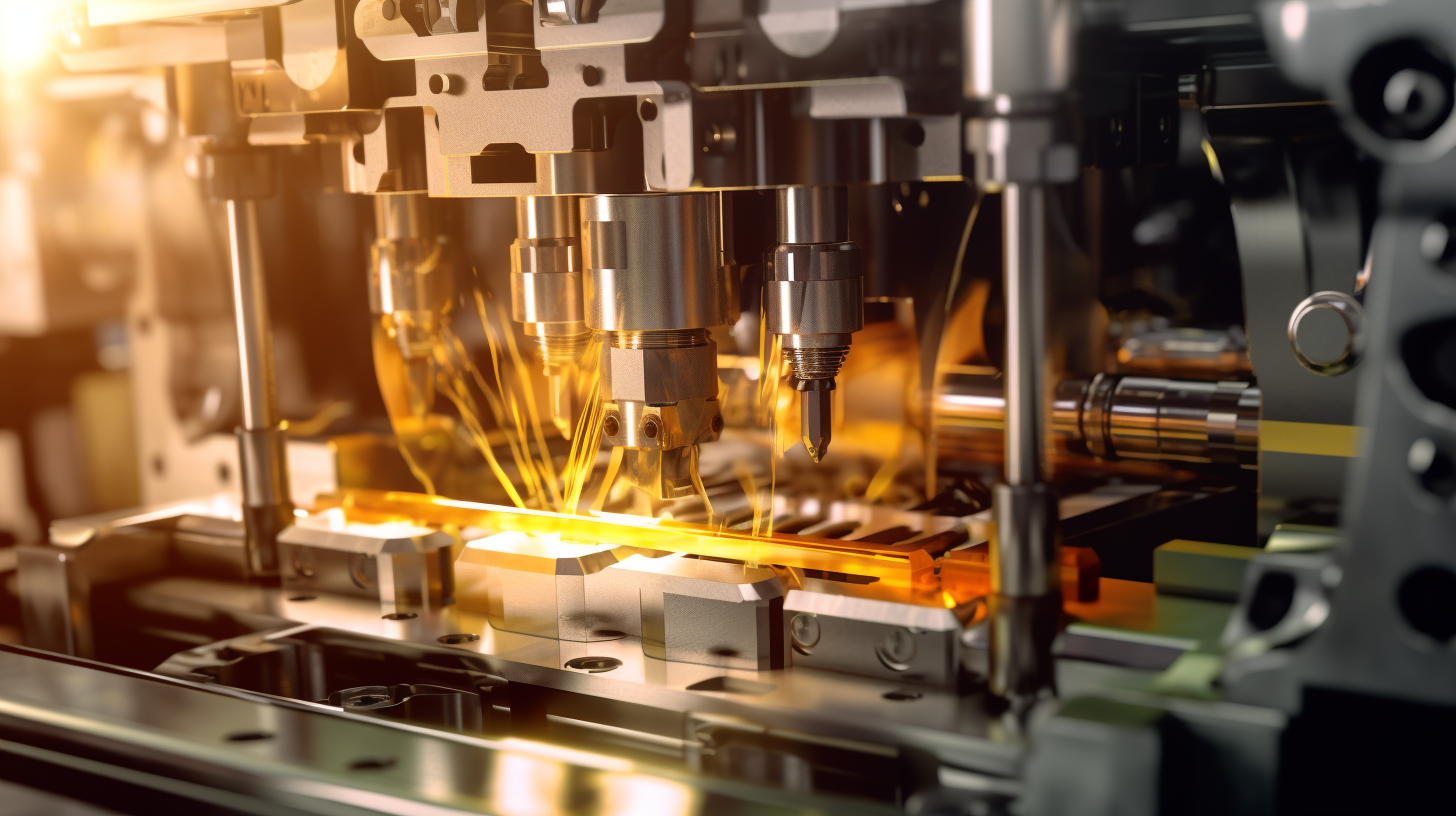

How Does Runner and Gate Design Influence Material Flow?

The runner system controls how material flows into the mold cavities, affecting filling efficiency and consistency. A poorly designed runner system can lead to imbalanced filling, increased scrap, and longer cycle times.

Optimizing the runner system:

Use balanced runner layouts to distribute material evenly.

Implement hot runners to minimize material waste and improve process efficiency.

Ensure smooth transitions between runners and gates to reduce turbulence and flow hesitation.

A well-designed runner system improves part consistency and minimizes waste.

Comparison of Key Mold Design Elements

| Mold Design Feature | Impact on Part Quality | Optimization Strategy |

| Gate Placement | Affects material flow, weld lines, shrinkage | Place gates in thick sections, avoid stress points |

| Cooling System Design | Prevents warping and shrinkage | Use conformal cooling and balanced circuits |

| Venting | Reduces air traps and burn marks | Place vents at flow endpoints, clean regularly |

| Runner System | Ensures uniform filling and reduces scrap | Use balanced or hot runner systems |

Key Tips for Optimizing Mold Design

Analyze Material Flow: Use simulation tools like Moldflow to predict flow behavior and identify potential defects.

Maintain Uniform Cooling: Ensure all areas of the mold cool evenly to avoid warping and residual stress.

Check and Adjust Venting: Properly positioned vents prevent defects like burn marks and incomplete filling.

Test and Validate: Prototype the mold and conduct trial runs to refine design before mass production.

Conclusion

Mold design plays a crucial role in achieving high-quality injection-molded parts by controlling material flow, cooling, venting, and runner systems. A well-optimized mold design minimizes defects, enhances part consistency, and improves production efficiency.

For expert assistance in optimizing mold design for your specific application, visit our resource center or contact us. Let’s help you achieve precision and reliability in your injection molding process!

Post time: Feb-06-2025